Auto Claims Trends: Frequency, Severity, Repair Costs, and Turnaround Times

Auto Claims Trends: Frequency, Severity, Repair Costs, and Turnaround TimesAs extreme weather events increase in frequency and severity, manufactures could face rising risks. In addition to property damage and business interruption, employee injury and environmental damage are also possible. In the face of increasing exposures, mitigating extreme weather risks in manufacturing will require a proactive stance.

The Rise of Extreme Weather

The U.S. Environmental Protection Agency (EPA) says that rising average global temperatures are linked to changing weather patterns, and extreme weather events are likely to become more frequent or intense as a result. These events could include large storms, floods, droughts and heatwaves.

The U.S. has already experienced a significant increase in extreme weather events with losses of at least $1 billion. According to the National Oceanic and Atmospheric Administration (NOAA), between 2000 and 2009, there were only 6.7 billion-dollar events per year, adjusted for inflation. Between 2010 and 2019, the annual average surged to 13.1. Between 2021 and 2023, the annual average has been a jaw-dropping 22.0. As of August 8, there have already been 19 confirmed events in 2024.

For manufacturers, the trend of rising extreme weather disasters is a significant threat that can lead to multiple risks.

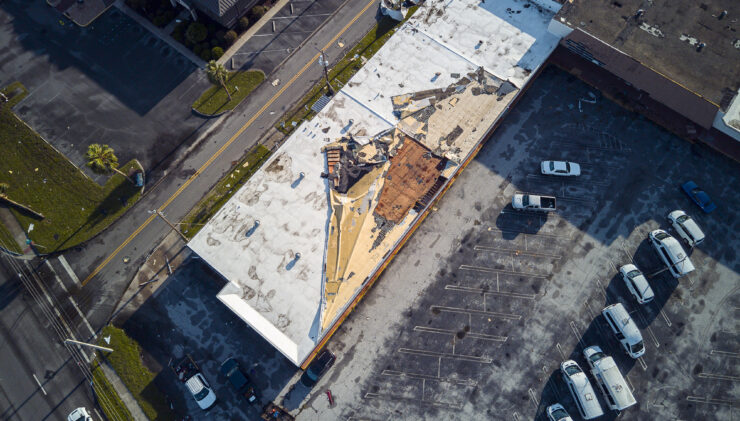

Risk 1: Property Damage

When business leaders think about manufacturing risks stemming from extreme weather, property damage may be the first threat to come to find. This is reasonable since property damage is a serious danger. A tornado, hurricane, wildfire or other major event could cause extensive damage. It’s not just the building that could be at risk, either. A company’s expensive manufacturing equipment could also experience damage.

Risk 2: Business Interruption

If a natural disaster damages a manufacturing site, operations will likely have to pause until the repairs can be completed. However, this is not the only way extreme weather could lead to business interruption.

- Evacuations could disrupt business. If a wildfire or hurricane is threatening a region, evacuations may be necessary to ensure everyone’s safety. Even if the building is spared and experiences no damage, this will result in business interruption.

- Events could disrupt the supply chain. A manufacturer does not need to experience a disaster directly for it to impact operations. If a supplier experiences business interruption due to a natural disaster, or if transportation is impeded, a manufacturer may not have the materials required to operate as usual.

Risk 3: Employee Injury

Extreme weather can also lead to worker injuries. For events like wildfires and hurricanes, manufacturing employers may have sufficient notice to evacuate the premises and get everyone to safety. However, for events that provide less notice, such as tornadoes, this may not always be possible.

Heat-related illness is another significant risk, and one that manufacturers may overlook. As temperatures rise, buildings may be harder to keep cool, and that could increase the danger. OSHA has proposed new heat standards that would protect both indoor and outdoor workers from heat injuries by establishing requirements for employers. According to ManufacturingDive, the new standard could require manufacturers to create and implement a work site heat injury and illness prevention plan and provide training. Manufacturers can prepare now – and help workers avoid injuries – by offering additional risks and increasing air conditioning. Some states have already enacted their own standards.

Risk 4: Environmental Damage

A natural disaster could trigger an environmental disaster. This is particularly concerning for manufacturers that store potential hazardous or unstable chemicals that could leak during a fire, storm or power outage.

In one well-known example of what can go wrong, the Arkema chemical plant experience an explosion in the aftermath of Hurricane Harvey. According to NBC News, the company and some employees faced criminal changes in the incident.

Mitigating Extreme Weather Risks

As the threat of extreme weather increases, this is a good time for manufacturers to reassess their risk management strategies.

- Do you have a work site heat injury and illness prevention plan? Even if this is not a requirement for your business right now, it may become a requirement in the near future.

- Do you have emergency plans for various types of extreme weather events? Consider how you will protect employees as well as property in the event of an emergency.

- Do you have business continuity plans? After a disruptive event, a business continuity plan can help minimize business interruption and losses.

- Could property improvements protect your company or its employees? Investing in upgrades could be a smart idea.

- Is your supply chain resilient? If one supplier suffered business disruption, how would it impact your business, and could you rely on alternative suppliers?

- Do you have sufficient insurance? Consider whether you have uncovered risks before an extreme weather event occurs.

Do you need manufacturing insurance coverage for extreme weather risks? Heffernan Insurance Brokers can help you review your insurance needs. Contact us.